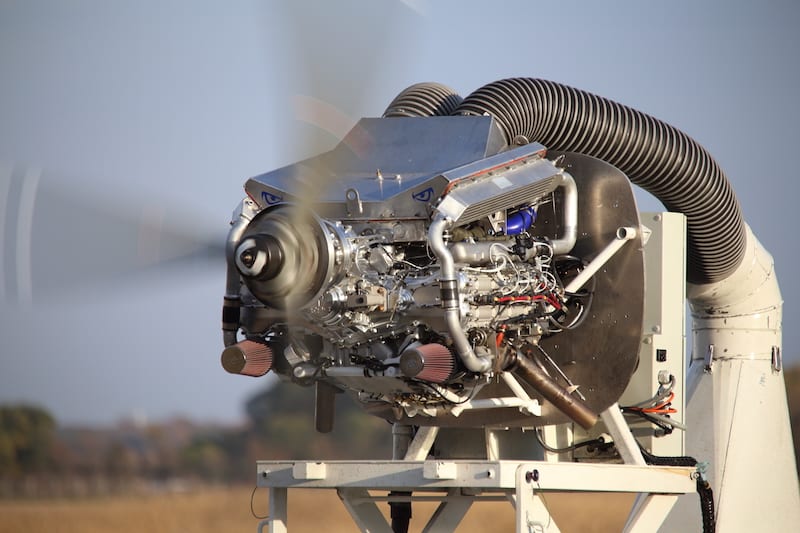

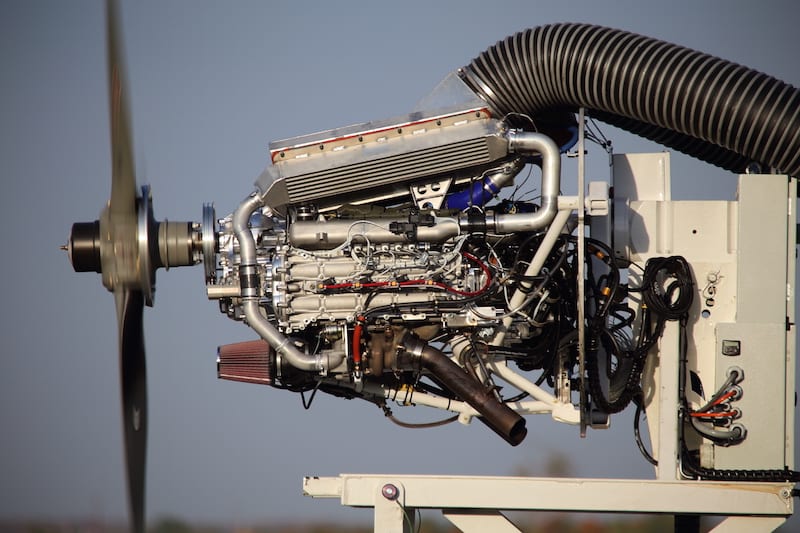

NEW RICHMOND, Wis. — Engineered Propulsion Systems reports it is making steady progress in its push toward FAA certification.

The company, which completed ground and flight tests on two concept engines last spring, has incorporated a number of refinements in the first pre-production engine, which recently passed the 100-hour mark in ground tests.

During the first 30 hours of running, the new engine confirmed predictions that all moving parts would run smoothly and that internal ports were functioning correctly in the movements of fuel, oil and gasses, according to company officials.

“We spent considerable time tweaking the calibrations and adjustments to assure optimal performance,” said EPS President Michael Fuchs. “That’s the only way to reach peak efficiencies and maximum horsepower. We have turned up 360 horsepower so far and expect to reach higher as the software is enhanced.”

The engine was subjected to a complete tear down at 5 hours and a partial tear down at 30 hours, he reports.

“There were no major issues,” said Fuchs. “This is encouraging since we incorporated hundreds of new mechanical components and systems.”

At the end of December, the first pre-production redundant Electronic Engine Control Units (EECUs) were put in service and are now undergoing testing.

As the company adds hours to the logbook, run times will increase. All of the data collected from running the first pre-production engine will be incorporated in the second in the series of pre-production engines

Flight tests with one of the pre-production engines are scheduled to begin with a company-owned Cirrus, at the hands of Dick Rutan, this spring.

Source: http://generalaviationnews.comEPS diesel engine logs 100+ hours